Insulating a metal storage shed is essential for protecting your stored items from extreme temperatures and moisture, ensuring a longer lifespan and better functionality. In this guide, we’ll explore how to insulate a metal storage shed, from selecting the right insulation type to step-by-step installation instructions.

Whether you’re looking to create a comfortable workspace or simply safeguard your belongings, our comprehensive tips will help you effectively insulate your metal storage shed, transforming it into a more usable and efficient space.

The Importance of Insulating a Metal Storage Shed

Insulating a metal storage shed is crucial for several reasons. Firstly, it helps regulate the internal temperature, providing a more stable environment for your stored items. Extreme temperatures, whether hot or cold, can cause damage to sensitive materials, tools, and equipment. By maintaining a

consistent temperature, insulation helps prolong the life of these items. Additionally, insulation acts as a barrier against moisture, which can lead to rust, mold, and mildew. This is particularly important for metal structures, as constant exposure to moisture can weaken the shed’s integrity over time.

Understanding Insulation Basics

Before diving into the specific steps for insulating your metal storage shed, it’s essential to understand the basics of insulation and the different types available. Insulation works by trapping air pockets, which slows down the transfer of heat. This helps maintain a steady temperature inside the shed, regardless of the weather outside. The most common types of insulation used in metal sheds include fiberglass batts, foam board, spray foam, and reflective insulation.

- Fiberglass Batts: These are among the most commonly used types of insulation. They are made of fine glass fibers and come in pre-cut panels that can be easily fitted between the shed’s framing. Fiberglass batts are cost-effective and offer good thermal resistance.

- Foam Board: Foam board insulation consists of rigid panels that provide excellent thermal resistance. It’s moisture-resistant, making it ideal for damp environments. However, it requires precise cutting to fit properly within the shed’s structure.

- Spray Foam: This type of insulation is applied as a liquid that expands into a foam, filling gaps and sealing air leaks. Spray foam offers superior insulation and is effective at reducing moisture and drafts, but it is generally more expensive than other types.

- Reflective Insulation: Made from aluminum foil laminated onto materials like cardboard or plastic, reflective insulation works by reflecting heat away from the shed. It’s lightweight and easy to install, making it a popular choice for metal sheds, especially in hot climates.

10 Methods How to Insulate a Metal Storage Shed

1. Assessing the Shed and Planning

Before beginning the insulation process, it’s crucial to assess the current state of your metal storage shed and plan accordingly. Measure the interior dimensions of the shed, including walls, roof, and doors, to determine the amount of insulation material needed. Identify any areas where moisture may be a problem and plan to address these before insulation.

Consider the purpose of the shed and the climate in your area to choose the most appropriate insulation materials. Proper planning ensures you select the right materials and have enough supplies, which saves time and effort during installation.

2. Sealing Gaps and Cracks

Sealing gaps and cracks in your metal storage shed is an essential first step to ensure the effectiveness of the insulation. Use caulk or expanding foam to fill in any openings around doors, windows, and seams where air and moisture can enter. Pay special attention to the roof and the base of the walls, as these are common areas for leaks.

Properly sealing these gaps prevents drafts, moisture ingress, and heat loss, creating a more stable environment for your insulation to work effectively. This step also helps to reduce energy costs and improve the overall comfort of the shed.

3. Installing a Vapor Barrier

A vapor barrier is crucial in preventing moisture from penetrating the insulation and causing mold or mildew. Install a polyethylene plastic sheet or specialized vapor barrier membrane on the interior walls and ceiling of the shed before adding insulation. Secure the barrier with adhesive or staples, ensuring there are no gaps or tears. Overlap the seams by at least six inches and seal them with waterproof tape to create a continuous barrier.

4. Using Rigid Foam Insulation

Rigid foam insulation is an excellent choice for metal storage sheds due to its high insulating value and moisture resistance. Available in panels or sheets, rigid foam is easy to cut and fit to the dimensions of your shed.

Attach the foam boards to the interior walls and ceiling using construction adhesive or screws with washers. Fill any gaps between the boards with expanding foam or caulk to ensure an airtight fit. Cover the foam insulation with a suitable interior finish, such as plywood or drywall, for added protection and a neater appearance.

5. Installing Reflective Insulation

Reflective insulation, also known as radiant barrier insulation, works by reflecting radiant heat away from the shed, keeping it cooler in the summer. This type of insulation consists of a layer of reflective foil laminated to materials like kraft paper, plastic film, or polyethylene bubbles.

Attach the reflective insulation to the interior walls and ceiling with staples or adhesive, ensuring the reflective side faces outwards to maximize heat reflection. Reflective insulation is lightweight, easy to install, and can be used in conjunction with other insulation types for improved thermal performance.

6. Applying Spray Foam Insulation

Spray foam insulation is a versatile and effective method for insulating metal storage sheds. This type of insulation expands on application, filling gaps, cracks, and irregular spaces, creating a seamless air barrier. Use a spray foam kit to apply the insulation to the interior walls, ceiling, and any hard-to-reach areas.

Follow the manufacturer’s instructions for application, including safety precautions such as wearing protective gear and ensuring proper ventilation. Spray foam provides excellent thermal insulation, reduces air infiltration, and adds structural strength to the shed. However, it can be more expensive and requires careful application to avoid over-expansion.

7. Insulating with Fiberglass Batts

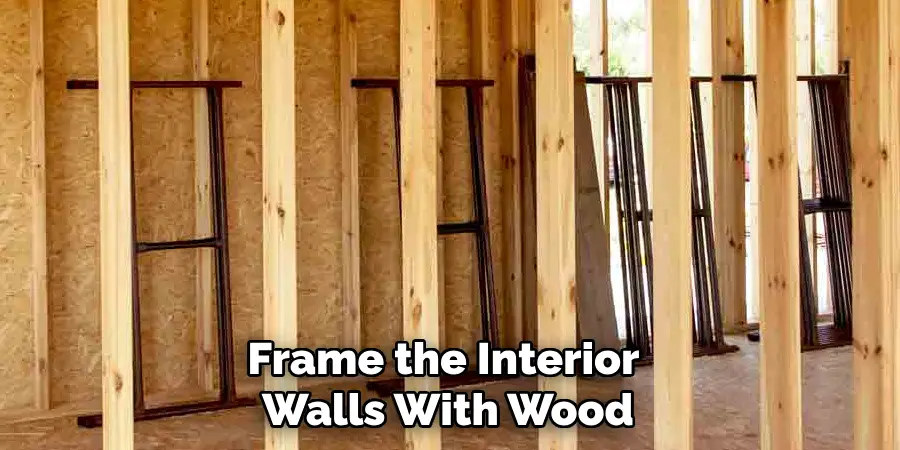

Fiberglass batts are a common and cost-effective insulation option for metal storage sheds. These batts are available in various thicknesses and R-values, allowing you to choose the appropriate level of insulation for your climate. To install fiberglass batts, first frame the interior walls and ceiling with wood or metal studs, creating cavities to hold the insulation.

Fit the batts snugly into the cavities, cutting them to size as needed. Secure the batts with wire mesh or staples, and cover them with a vapor barrier if not pre-faced with one. Finish by installing a suitable interior wall covering, such as plywood or drywall. Fiberglass batts provide good thermal resistance and are relatively easy to install.

8. Using Foam Board Insulation

Foam board insulation is another effective option for insulating metal storage sheds. These rigid panels are made from polystyrene, polyisocyanurate, or polyurethane and offer high insulating values with minimal thickness. Cut the foam boards to fit the dimensions of your shed’s walls and ceiling, and secure them with construction adhesive or screws.

Seal the joints and edges with tape or expanding foam to prevent air leaks. Foam board insulation is moisture-resistant and provides excellent thermal performance. It can be used alone or in combination with other insulation materials for enhanced insulation.

9. Adding Insulated Panels

Insulated panels, or structural insulated panels (SIPs), are a comprehensive insulation solution that combines insulation and structural support. These panels consist of a layer of foam insulation sandwiched between two sheets of oriented strand board (OSB) or other structural materials. Install insulated panels directly onto the shed’s frame, securing them with screws or nails.

The panels provide continuous insulation and structural integrity, reducing the need for additional framing or finishing materials. Insulated panels are highly efficient and offer superior thermal performance, but they can be more expensive and require precise installation.

10. Maintaining and Inspecting Insulation

Regular maintenance and inspection of your shed’s insulation are crucial to ensure long-term effectiveness. Periodically check for signs of moisture infiltration, such as mold, mildew, or water stains, and address any issues promptly. Inspect the insulation for damage or deterioration, replacing any compromised sections as needed. Ensure that the vapor barrier remains intact and reseal any gaps or tears.

Maintaining proper ventilation within the shed helps prevent moisture buildup and extends the life of the insulation. Regular upkeep ensures that your metal storage shed remains well-insulated and protected from the elements.

Conclusion

Insulating your metal storage shed is a crucial step in protecting your belongings and maintaining a comfortable environment inside the shed. With a variety of insulation options available, from rigid foam and reflective insulation to spray foam and insulated panels, you can select the best solution based on your specific needs, budget, and climate conditions.

Proper installation and regular maintenance of the insulation will ensure its effectiveness over time, keeping your shed well-insulated and energy-efficient. Thanks for reading, and we hope this has given you some inspiration on how to insulate a metal storage shed!

About

Outdoor Fixes is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions.

His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques,

fostering designs that are both practical and environmentally conscious. As the author of diy,

outdoorfixes delves into the art and science of outdoorfixes-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Outdoor Fixes) Focus on sustainable design, industry-driven projects,

and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in outdoorfixes.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production

techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Outdoor Fixes his insights on indoor design processes, materials, and strategies for efficient production.

His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.