Sprinkler systems play a crucial role in lawn and landscape health, and at the heart of these systems are solenoids—electromagnetic devices responsible for controlling the flow of water to your sprinkler zones. When a sprinkler zone won’t turn on or off as expected, or when parts of the lawn are under- or over-watered, a common culprit is the solenoid.

Understanding how to find solenoid for sprinklers is essential for troubleshooting irrigation issues, performing timely repairs, and maintaining efficient water use. In this guide, you’ll learn about solenoid functions, signs of malfunction, effective search and testing methods, and how to ensure proper operation for reliable irrigation.

Understanding Sprinkler System Solenoids

Sprinkler system solenoids are small but vital components typically located atop or inside an irrigation control valve. They respond to electrical signals from the irrigation controller, opening or closing valves to regulate water flow to specific zones. Solenoids make automatic irrigation possible by converting electric signals into mechanical movement within the system.

Types of Solenoids Found in Sprinkler Systems

You’ll generally encounter two types of solenoids in sprinkler systems: AC (alternating current) and DC (direct current). AC solenoids are most common in wired residential and commercial systems, while DC solenoids are often found in battery- or solar-powered setups. Always identify the type in your system before sourcing replacements.

Signs of a Malfunctioning Solenoid

A faulty solenoid can prevent a zone from receiving water or cause it to remain on continuously, leading to patchy lawns, water waste, or high utility bills.

System-wide Indicators

Typical symptoms include zones not responding to controller commands, valves that won’t open or close, or erratic operation—such as sprinklers running when they shouldn’t or ignoring scheduled programs.

Testing the Solenoid

Initial tests include listening for a clicking sound from the valve when the system is activated—no click may indicate a disconnected or dead solenoid. Using a multimeter to check for electrical continuity and resistance can confirm if the solenoid is functioning internally. Also, look for frayed wires and obvious wear.

Tools and Preparations for Locating a Solenoid

Thorough preparation streamlines the search and reduces the risk of accidental damage.

Essential Equipment

Helpful tools include a valve locator (which transmits signals to help find buried valves and their solenoids), a wire tracer, a standard multimeter, a trowel, gloves, and the sprinkler system’s documentation if available.

Pre-Search Preparations

Start by turning off the irrigation system’s power to prevent electrical accidents. Review your system’s layout or manual to track valve locations and the wiring path between the controller and the solenoids.

How to Find Solenoid for Sprinklers: Identifying Process

Identifying the precise location of a solenoid can save significant troubleshooting time and prevent unnecessary excavation.

Following the Wiring

Begin at the irrigation controller, and visually check which wires lead toward the yard or garden. These control wires typically run along the main pipes and connect to the valve boxes that house the solenoids. Walk the property, following possible wire routes, and look for valve boxes set slightly below the surface, often hidden under grass or mulch.

Using a Valve Locator Tool

A valve locator simplifies underground searches by transmitting a tone through the valve’s control wire or pipe. Hold the receiver and scan the ground systematically. Listen for increases in volume or tone frequency, which indicate you’re near the buried valve box (and thus the solenoid inside).

Manual Search Methods

If you don’t have electronic tools, carefully probe the lawn with a trowel or sturdy stick to feel for hard plastic boxes (valve covers). Look for slightly raised or sunken areas, or follow the sprinkler main lines visually if any portions are exposed.

Confirming the Solenoid Location and Condition

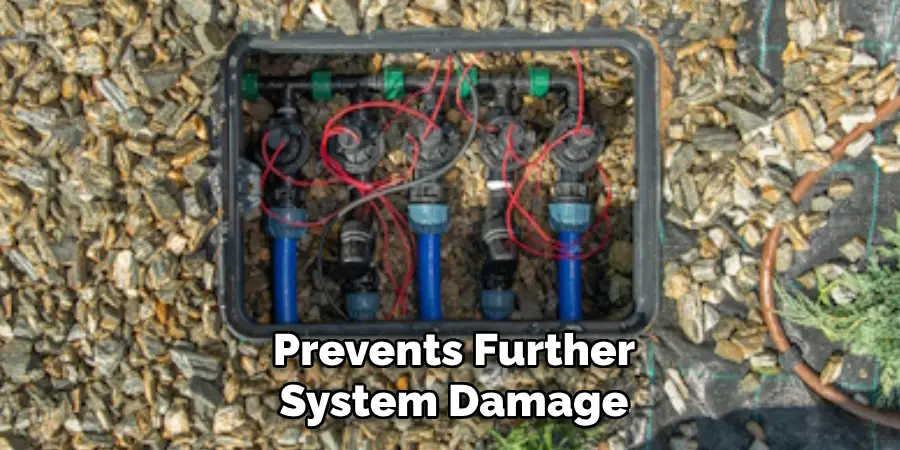

After locating the valve box and opening its cover, you’ll usually find one or more solenoids attached to the control valves.

Testing the Solenoid Directly

Use a multimeter to check for continuity across the two wire terminals on the solenoid. A reading of 20–60 ohms (for most residential models) typically indicates good health. No reading or obvious open circuit means the solenoid likely needs replacement.

Inspecting for Damage

Visually inspect the solenoid for signs of cracks, corrosion, burned spots, or broken wires. Debris, standing water, or mud may indicate leaks or exposure issues that could also affect the solenoid’s operation.

Repairing or Replacing a Solenoid

Addressing solenoid issues promptly ensures consistent irrigation and prevents further system damage.

When to Repair

If the solenoid appears intact but connections are loose or contacts are dirty, tighten wires and gently clean metal contacts. Sometimes a stuck plunger can be freed by tapping gently or flushing the valve.

When to Replace

If the solenoid fails electronic testing or shows physical damage, replace it with a compatible model matching voltage and thread size. Turn off the water, unscrew the old solenoid, and carefully thread in the new unit before reconnecting wires and restoring power.

Preventing Solenoid Issues in the Future

Routine maintenance and smart system care extend the life of solenoid components.

Maintenance Practices

Schedule seasonal inspections: clear debris from valve boxes, check for frayed or exposed wires, and test valve operation via the controller regularly to catch minor problems early.

Environmental Protection

Position valve boxes in areas less prone to flooding or compaction. Ensure boxes remain unobstructed by plants or mulch, and consider weatherproofing exposed connections in climates with frequent rain or extreme temperatures.

Avoiding Common Mistakes When Looking for Solenoids

Navigating sprinkler systems can be tricky—avoid these pitfalls for an efficient and safe process.

Common mistakes include misreading wiring diagrams (mark wires before disconnected), confusing irrigation pipe routes with wiring runs, or forgetting to turn off electricity before working on system components. Slow, deliberate work and double-checking diagrams or seeking help if unsure can spare costly repairs.

Benefits of a Well-Maintained Solenoid System

A well-maintained solenoid system can offer numerous benefits to both residential and commercial property owners. Some of the key advantages include:

- Consistent Watering: With a properly functioning solenoid system, you can ensure that your lawn or garden receives consistent watering. This is important for maintaining healthy plants and preventing uneven growth.

- Time Savings: A well-maintained solenoid system can save you time by automating the watering process. You no longer have to manually turn on sprinklers or hoses, allowing you to focus on other tasks.

- Cost Savings: By using a solenoid system with an automatic timer, you can avoid over-watering and potentially wasting water. This can lead to cost savings on your water bill.

- Customization: With a solenoid system, you have the ability to customize your watering schedule based on the specific needs of your lawn or garden. You can adjust the frequency and duration of watering to suit different types of plants or weather conditions.

- Remote Control: Some solenoid systems come with remote control capabilities, allowing you to turn on or off the system from a distance. This is especially useful for those unexpected rainy days when you don’t need to water your lawn or garden.

When to Seek Professional Help

While solenoid systems offer a convenient and efficient way to water your lawn or garden, they can also be complex and require professional help for installation and maintenance. If you are not familiar with irrigation systems or if you encounter any issues with your system, it is best to seek the help of a professional.

A qualified irrigation specialist will be able to install the system properly and ensure that all components are functioning correctly. They can also diagnose any problems and make necessary repairs or adjustments. Investing in professional help may save you time, money, and stress in the long run.

Frequently Asked Questions

How Often Should I Inspect My Sprinkler System?

It’s recommended to inspect your sprinkler system at least once every season to ensure it operates efficiently and to address any potential issues early.

What Are Common Signs of Solenoid Failure?

Common signs include zones failing to turn on or off, inconsistent water pressure, or unusual noises coming from the valve box.

Can I Replace a Solenoid Myself?

Yes, if you are comfortable with basic tools and wiring, you can replace a solenoid yourself. However, if you are uncertain, it’s best to consult a professional.

How Do I Identify Leaks in My Irrigation System?

Look for unusually wet areas, lower water pressure, or increasing water bills as indicators of potential leaks in your system.

What Maintenance Can Prolong the Life of My Sprinkler System?

Regularly cleaning components, checking for clogs, and ensuring proper winterization can prolong the lifespan of your sprinkler system.

Conclusion

Knowing how to find solenoid for sprinklers is a valuable skill for any property owner or landscaper. By understanding solenoid function, using proper tools, and following step-by-step search and testing methods, you can resolve irrigation issues quickly and keep your landscaping vibrant. Regular maintenance and proactive problem-solving will reduce water bills, prevent landscape damage, and ensure your sprinkler system remains efficient for seasons to come.

About

Outdoor Fixes is a distinguished figure in the world of Diy design, with a decade of expertise creating innovative and sustainable Diy solutions.

His professional focus lies in merging traditional craftsmanship with modern manufacturing techniques,

fostering designs that are both practical and environmentally conscious. As the author of diy,

outdoorfixes delves into the art and science of outdoorfixes-making, inspiring artisans and industry professionals alike.

Education RMIT University

(Melbourne, Australia) Associate Degree in Design (Outdoor Fixes) Focus on sustainable design, industry-driven projects,

and practical craftsmanship. Gained hands-on experience with traditional and digital manufacturing tools, such as CAD and CNC software.

Nottingham Trent University

(United Kingdom) Bachelor’s in outdoorfixes.com and Product Design (Honors) Specialized in product design with a focus on blending creativity with production

techniques. Participated in industry projects, working with companies like John Lewis and Vitsoe to gain real-world insights.

Publications and Impact

In diy, Outdoor Fixes his insights on indoor design processes, materials, and strategies for efficient production.

His writing bridges the gap between artisan knowledge and modern industry needs, making it a must-read for both budding designers and seasoned professionals.